Komatsu Ltd.

Squish Used for ICT Monitor GUI Testing on Latest Construction Equipment

Automation Reduces Man-hours by 21.4% and Increases Test Coverage to 100%.

21.4%

of man-hours reduced by test automation

100%

test coverage

About Komatsu

The machinery repair division of Takeuchi Mining Industry, which operated the Yusenji copper mine in Komatsu City, Ishikawa Prefecture, became independent in 1921 and was founded as Komatsu Iron Works. Since then, the company has grown to one of the world's leading construction equipment manufacturers, providing products, services, and solutions worldwide, focusing on the construction, mining, and industrial machinery fields. Today, the company develops, produces, and sells construction equipment, industrial machinery, and special vehicles used in civil engineering, demolition, industrial waste and recycling, mining, quarrying, forestry, agriculture and livestock, logistics, social infrastructure, and other fields in over 190 countries and regions around the world.

https://www.komatsu.jp/ja

Reasons to choose Squish

Expanded scope and functionality of automated testing to streamline the test process

Automated GUI testing reduced man-hours by 21.4% compared to manual testing

Automation enabled testing at all levels, expanding the coverage to 100%

Integration with OCR functionality enabled multilingual test evaluation across 27 languages

Komatsu, a global provider of products and services in the construction, mining, forestry, and industrial machinery fields, has adopted Squish to automate GUI testing of ICT monitors installed on its latest construction equipment. The company has successfully expanded the scope and functionality of automated testing, while also reducing testing effort and enhancing test coverage.

Manual testing requires significant effort - Started exploring automated testing of ICT monitors

Komatsu is a construction equipment manufacturer that supplies more than 190 countries and regions around the world with mining equipment for the supply of mineral resources, construction equipment for infrastructure development and urbanization, industrial equipment for manufacturing production, and forestry equipment for sustainable use of wood. In recent years, the company has pioneered the use of ICT in the industry and is attracting attention and expectations both domestically and internationally with the introduction of Komtrax, which remotely checks machine operating status and warning information, and Smart Construction, which creates safety and productivity by visualizing and optimizing the entire construction production process.

Field Automation Development Center, Development Division

Komatsu

Since the 2000s, ICT-based construction using positioning technologies and 3D design data has helped build the environment needed to deploy Smart Construction. Mr. Takayuki Nishihata, Group Manager of Construction Equipment Automation Group 3, Field Automation Development Center, Development Division, says,

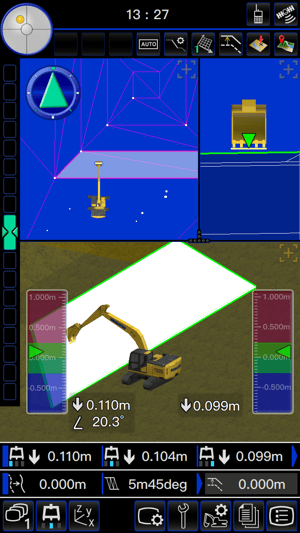

My team is developing on-board ICT components for ICT hydraulic excavators and ICT bulldozers that support information driven construction. The Electronic Control Unit (ECU) touch panel monitor (ICT monitor) in the construction equipment leverage Global Navigation Satellite System (GNSS) to visualize machinery positions in digital space, enabling terrain-adaptive construction guided by 3D design data from engineering drawings.

For functional testing of the application in the ICT monitor, the team uses Qt Group’s Squish GUI test automation tool. Previously, functional tests were primarily carried out manually, with only a limited attempt to automate some of them using a capture-and-replay tool. Mr. Yoshito Kumakura, Senior Engineer, Construction Automation System Development Group 3, Field Automation Development Center, Development Division, recalls,

Because ICT monitors require regular software updates, we need to rerun many test cases. At that time, those tools required us to enter geographic coordinates and waiting times manually, and they could only check part of each violation. This made it difficult to fully automate our process.

Mr. Yoshito Kumakura

Senior Engineer

Construction Automation System Development Group 3

Field Automation Development Center, Development Division

Komatsu

Select Squish for Its Compatibility with Qt GUI development tool and high usability

The team decided to try automation, giving priority to tests that are repeated regularly and for areas where specifications changes are minimal. After evaluating various solutions, the team found that Squish fulfilled all their requirements. The team identified two main advantages. First, the team was already using Qt for developing the ICT monitor’s user interface, and Squish for Qt offered reliable test automation through its seamless integration. Second, the tool allows easy access to text and positional information simply by specifying object names. Recognizing Squish’s convenience, the team officially adopted it in November 2014, and began implementing it step by step. Currently, the team uses Squish to automate testing for geographic coordinate input/output values and to verify multilingual functionality.

The team’s automated testing stands out because it’s built around three key components: (1) scenarios (scripts written based on the manual test cases), (2) libraries (scripts describing generic processing used in the scenarios), and (3) data resources (CSV files containing changed test levels). Mr. Kumakura, who developed the system, explaines the significance.

This is to keep the system maintainable and adaptable. We thought that if we conducted testing without libraries, similar content would be written in various locations, and updates could easily be missed when changes are made.

To support multiple applications, libraries are grouped into two categories: a common library for all applications and dedicated libraries for each application. This approach enables automated testing of common actions—like button clicks and file operations—across multiple applications.

Additionally, because the ICT monitor communicates directly with the ECU, the team developed a communication emulator. This emulator works with Squish to automate the exchange of data between components.

Automated GUI testing on ICT monitors reduced man-hours over 20% compared with the past manual testing

Three key benefits were achieved by using Squish: The first is the expansion of both the scope and capabilities of automated testing. With shared libraries now easier to create and use across applications, testing has become much more efficient—making it practical to build and maintain large-scale systems.

Second, GUI testing time dropped. By replacing manual processes, the required effort of 11 man-months decreased by 2.4 man-months—a 21.4% reduction in total man-hours.

The third benefit is improved test coverage. Previously, with manual testing, only about 1% of functions could be checked—roughly 75 hours’ worth—since testing was limited to certain levels. After introducing automated testing, coverage has expanded to 100% across all levels.

These results reflect the team's expertise and practical experience. Instead of automating every test, Mr. Kumakura followed a careful process to decide which tests to automate.

Our process begins with evaluating whether manual testing is consuming substantial time and resources. Next, we consult with the manual testing lead to get their perspective on the quontative value of automation. If automation appears worthwhile, we estimate the required work hours and assess its potential impact using clear, measurable data.

Because current ICT monitors support up to 27 languages, the OCR feature—integrated with Squish—enables multilingual testing by including all supported languages in test criteria. "A test passes only if all three criteria are satisfied: string matching, display range validation, and OCR verification," Mr. Kumakura explains.

Efficiency and Reusability in Testing: Key Reasons for Long-Term Use of Squish

Looking ahead, the team plans to automate tests directly from the specifications document. Mr. Kumakura says,

Automated testing is carried out based on manual test scenarios, with shared procedures structured into reusable libraries. Therefore, as long as the specification format is clearly and consistently defined, it is considered feasible to generate and execute automated tests directly from the specification document.

Mr. Nishihata reflects on the efforts.

We find that ICT monitors work exceptionally well with Squish. Touch panel specifications are frequently updated to meet evolving user needs. In the past, we had to specify the position of each coordinate and recreate the test tool. With Squish, we can follow the function by simply specifying the object name without positional coordinates on the screen. This streamlined the testing process and increased test case reusability. This unique capability sets Squish apart from other solutions and is the reason why we have relied on it for a long time.

Komatsu’s ICT components are anticipated to address a wide range of issues faced by construction sites globally, including labor shortages and enhanced safety requirements. Qt Group will continue to support Komatsu's challenges and innovations by enhancing and optimizing Squish's capabilities.

|

|

Test Automation Case Study with Squish

JSOL | Tested with Squish

JSOL Corporation enhances quality assurance in JMAG using Squish, automating 40% of test cases and reducing workload by 85%, ensuring efficient and re...

Read More

Success Story ABB | Squish for Qt

Discover the winning combination of stability and convenience with Squish for Qt with the ABB Group. Elevate your testing process today!

Read More

Success Story Skyguide | Squish for Qt

Skyguide, headquartered in Geneva, Switzerland, is a company with a longstanding history of contribution to the development of Swiss aviation.

Read More