Qt Group at SPS

Stop by booth 5-138 to learn why we are your one-stop partner for industrial software. Explore the latest demos and solutions that power the future of automation.

Experience Qt Experts on SPS Stage

Accelerating Innovation How Qt is Transforming Cross-Platform Development in Industrial Automation

Tue 25th, 16:00 - 16:20: Stage Hall 1

> Michele Rossi, Industry Director Industrial Automation.

Architectural Decay: The Real Threat to Legacy Compliance and How to Regain Control

Wed 26th, 14:00-14:20: Stage Hall 3C

> Daniel Simon, Distinguished Software Engineer

Accelerating Industrial AI Applications

Thu 27th, 14:00-14:20: Stage Hall 6

> Michele Rossi, Industry Director Industrial Automation

Demos

Have a sneak peek at all the demos and solutions present at Booth 5 - 138.

Digital Twin Tech

Robot Arm Control Game via Graphical User Interface

- Showcasing Qt’s capabilities in high-precision monitoring and control systems, the demo leverages Digital Twin technology to synchronize a real-life robotic arm with its digital counterpart. Users can manually control the robot through an intuitive interface, moving it precisely to pick up objects within a set time, for seamless interaction and precision.

- Key Qt functionalities used: Qt Bridge for Figma, Qt Quick 3D, Qt Remote Objects

Visual QA Assistant

- Visual QA Assistant = AI + Camera + Qt UI

- Scans real physical parts using a camera

- Detects defects using Qt AI Inference API

- Provides natural language explanation of what’s wrong and why

- Displays result visually (overlay, image mark-up) and via voice feedback

- Running on: Asus Mini-PC NUC (to host Qt and LLM model) and for the Computer Vision (CV) model using Renesas V2H board

Built together with: ![]()

Powered by: ![]()

Quality Assurance Tools

Squish

- Automated GUI testing tool

- Squish for MCUs

- Squish AI

Axivion

- Static code analysis and architecture verification

Coco

- Code coverage analysis

CRA Kiosk

Learn with our interactive kiosk are you prepared for the upcoming CRA regulations from all necessary topics and concerns.

FactoryPulse

-

This demo showcases an integrated industrial monitoring system powered by the Qualcomm Dragonwing™ IQ-9075 Evaluation Kit (EVK), which delivers industrial-grade AI performance at the edge and Qt’s cross-platform GUI framework and multiple, integrated AI pipelines. Together, this solution enables real-time anomaly detection, enhanced personnel safety, and defect identification—all with ultra-low latency thanks to the new Dragonwing IQ-9075 EVK and the developer-friendly Qt Framework!

- Built together with:

Relevant Customer Stories Written with Qt

Learn how Siemens uses Qt Framework in Industrial Automation for its industrial stability, robustness, and industry-grade quality.

Learn how Bosch Software and Digital Solutions partners with Qt to help global customers accelerate their digital transformation journeys.

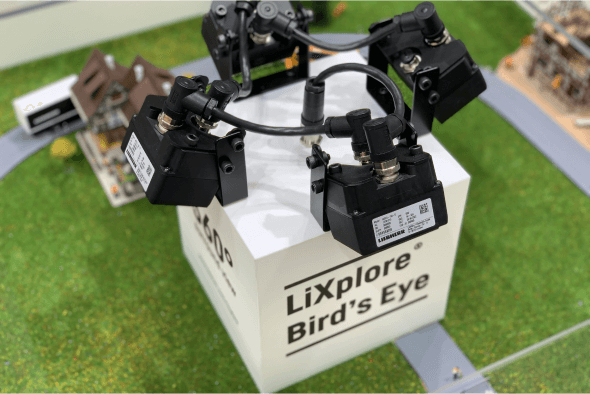

Liebherr-Electronics and Drives GmbH offers mobile machine operators detailed views of their working environment, with strong technical support from Qt and responsive contacts.

The ABB Group uses Squish GUI Tester in protection relay development to ensure quality and safety, with scripts built by modeling the UI structure rather than recording.

.webp)

Novatron uses the Qt framework in heavy-duty equipment control systems for seamless data flow and sensor-based visualizations, emphasizing the need for reliable systems in their work.

Discover how SICK AG, a global leader in intelligent sensor technology, boosts code quality and speeds up time-to-market using Axivion Static Code Analysis from Qt Quality Assurance.

Explore Our Resources Before SPS

How to Modernize Legacy SCADA Apps

With too many Supervisory Control and Data Acquisition (SCADA) systems reliant on legacy frameworks like .NET or outdated MFC technology, today’s industrial automation systems are in urgent need of modernization.

Cybersecurity in Industrial Automation: Securing the Future of Industrial Systems

This eBook explores risks and common challenges, focusing on cybersecurity and cyber-resilience measures to prevent vulnerabilities and recover from attacks.

Quality Assurance for Automation

Create dependable Industrial IoT devices that can be operated in full safety and security, with or without wireless connectivity, through any type of input/output interface—including physical knobs and touch screens.

Maximize Productivity and Quality with Scalable Industrial IoT Solutions

Create efficient, flexible, and reliable industrial IoT solutions and SCADA systems that scale across devices, verticals, and functions.

Assure Safety and Security in Industrial Automation

Ensure functional safety and compliance to meet the demanding industry standards and guidelines. Our customizable and scalable tools help you enhance your productivity.